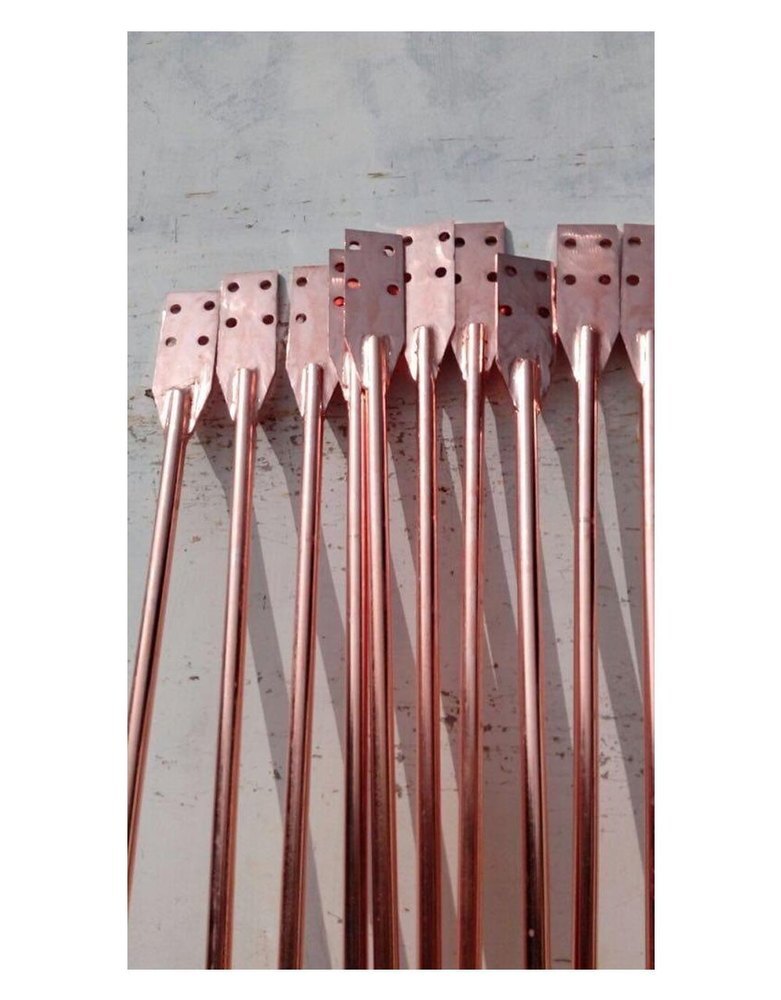

copper bonded earth rod

Price 750.00 INR/ Piece

copper bonded earth rod Specification

- Purity

- 99%

- Diameter

- 17.2mm

- Strength

- High3000 mm

- Copper Thickness

- 17.2 Millimeter (mm)

- Product Type

- Solid Copper Bonded Earth Rod

- Material

- Copper Bonded Steel

- Application

- Industrial

- Function

- High Functionality

- Shape

- Rectangle

- Weight

- 14kg

- Color

- Copper

- Warranty

- Yes

copper bonded earth rod Trade Information

- Minimum Order Quantity

- 50 Number

- Supply Ability

- 10000 Per Month

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About copper bonded earth rod

Copper Bonded Earthing Rod is a robust safety element that is commonly used in electrical grounding systems to protect circuits from current surges. It is manufactured by using premium-quality copper that provides a low resistive path to ensure efficient transfer of surge currents into the ground. The offered earthing rod is coated with a non-corrosive coath that provides excellent protection from the outdoor environment. It can be customized to different lengths as per the applications where it is going to be installed. It is fixed with a punched plate at its end to easily connect the wire. Buy from us Copper Bonded Earthing Rod in bulk at a low priceSuperior Conductivity for Industrial Use

The copper bonded earth rod is designed for demanding industrial environments, combining high-strength steel with a thick, pure copper layer. Its exceptional conductivity and 99% copper purity offer reliable safety against electrical shocks and surges, playing a critical role in grounding systems across factories and large-scale operations.

Durable Construction for Long-Lasting Performance

With a substantial weight of 14kg and a 17.2mm diameter, this earth rod ensures stability and resistance to harsh environmental conditions. The robust copper bonding significantly enhances its resistance to corrosion, providing an extended lifespan even in challenging Indian climates and soil conditions.

FAQs of copper bonded earth rod:

Q: How should the copper bonded earth rod be installed for optimal grounding?

A: The rod should be vertically driven into the earth at the desired location, ensuring it reaches a depth of at least 3000mm for effective grounding. It is essential to use grounding clamps and proper tools during installation to maintain the integrity of the copper coating.Q: What makes this copper bonded earth rod suitable for industrial applications?

A: Its high functionality, 14kg weight, and 17.2mm copper thickness offer exceptional strength and conductivity. The 99% pure copper bonding ensures superior corrosion resistance and reliable electrical performance in demanding industrial environments.Q: When should this earth rod be replaced or inspected?

A: Periodic inspections are recommended, especially in corrosive soil conditions. Replacement is advised if there are visible signs of wear, corrosion, or a significant reduction in conductivity to maintain grounding efficacy.Q: Where can this product be sourced or supplied from?

A: Manufactured, supplied, and traded in India, the copper bonded earth rod is available through authorized distributors, manufacturers, and industrial suppliers across the country.Q: What is the process behind the copper bonding of the steel rod?

A: The steel rod undergoes a molecular bonding process where 99% pure copper is coated over the steel surface, creating a uniform, durable, and high-conductivity layer that protects against corrosion and mechanical damage.Q: How does the copper thickness benefit the grounding system?

A: A generous 17.2mm layer of copper provides enhanced conductivity and protection, ensuring a reliable and long-lasting electrical grounding connection with minimal maintenance over the years.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earthing Electrode Category

chemical earthing installation services

Price 2200 INR / Number

Minimum Order Quantity : 50

Copper Thickness : 100250 microns

Purity : Copper Purity above 99%

Diameter : 16mm, 17.2mm, 25mm, 32mm (as required)

Product Type : Chemical Earthing Installation Services

Industrial GI Earthing Electrode

Price 600.00 INR / Piece

Minimum Order Quantity : 50

Copper Thickness : 1.6mm Millimeter (mm)

Purity : 99%

Diameter : 80mm Millimeter (mm)

Product Type : Industrial GI Earthing Electrode

Copper Earthing Bonded Rod

Price 1800 INR / Piece

Minimum Order Quantity : 1 Thousand

Copper Thickness : 1.6 Millimeter (mm)

Purity : 99%

Diameter : 76mm Millimeter (mm)

Product Type : Gi Earthing Electrode Rod

earthing rod

Price 1800 INR / Thousand

Minimum Order Quantity : 100 Units

Copper Thickness : 1.6mm Meter

Purity : 99%

Diameter : 76mm Meter (m)

Product Type : Gi Earthing Rod

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free