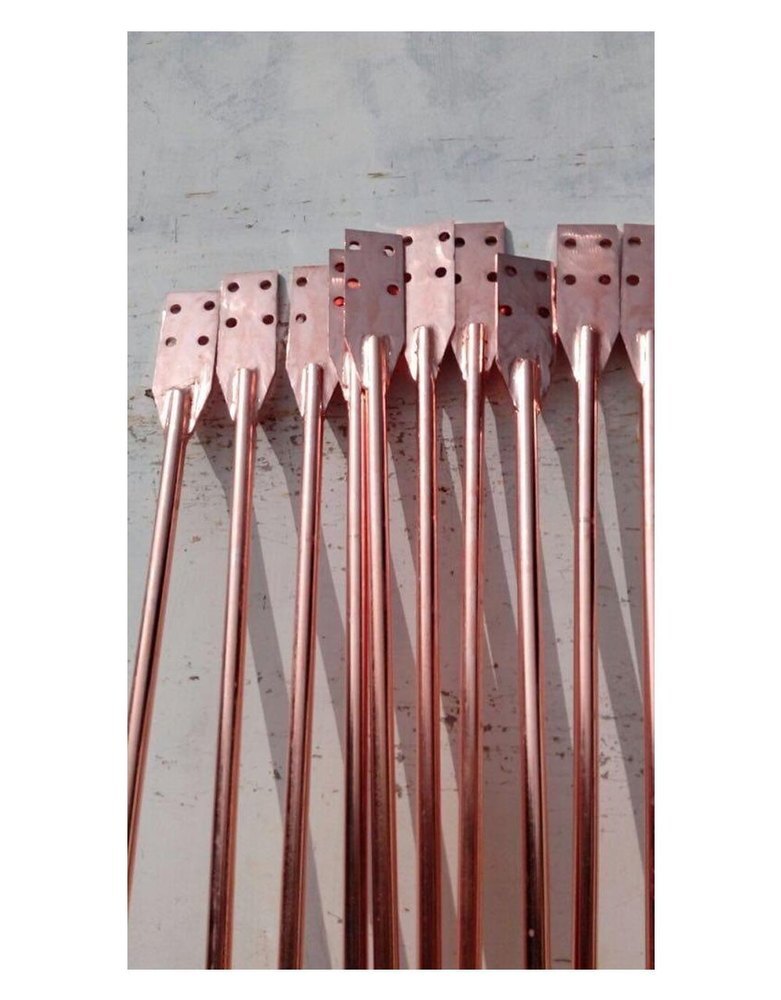

chemical earthing installation services

Price 2200 INR/ Number

chemical earthing installation services Specification

- Diameter

- 16mm, 17.2mm, 25mm, 32mm (as required)

- Tensile Strength

- 600 N/mm

- Strength

- High Mechanical Strength upto 600 N/mm

- Purity

- Copper Purity above 99%

- Life Span

- Over 25 Years in Normal Soil Conditions

- Copper Thickness

- 100250 microns

- Product Type

- Chemical Earthing Installation Services

- Material

- Copper Bonded Steel / GI (Galvanized Iron)

- Application

- Electrical Earthing for Protection of Equipment and Personnel

- Function

- Provides low resistance earthing for electrical safety

- Shape

- Rod/Cylindrical

- Surface Treating

- Copper Bonded / Galvanized

- Tolerance

- 5 mm

- Dimension (L*W*H)

- Standard sizes (as per requirement), e.g., 2m x 60mm

- Weight

- Approx. 715 kg (depends on size)

- Color

- Copper Brown / Metallic Grey

- Service Type

- On-site Installation with Testing

- Moisture Retention

- Excellent due to use of Backfill Compound

- Corrosion Resistance

- High; Suitable for Aggressive Soil Conditions

- Resistivity Achieved

- Less than 1 Ohm

- Minimum Order Quantity

- As per requirement (generally 1 set or more)

- Installation Method

- Direct Driven or Augered Hole with Backfill Compound

- Operating Temperature Range

- -10°C to +60°C

- Applicable Standards

- IS 3043, IEEE 80, IEC 62561-2

- Packing Type

- Standard Packing (Carton/Bag)

- Backfill Material

- Carbon Based Conductive Compound

chemical earthing installation services Trade Information

- Minimum Order Quantity

- 50 Number

- Supply Ability

- 1000 Per Day

- Delivery Time

- 2 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About chemical earthing installation services

| Size of Conductor | 50*6mm |

| Length of Rod | 1-2-3 meters |

| Material | Galvanised iron |

| Diameter | 76-50 mm |

| Surface Treatment | Galvanized |

allow the rod to be installed at least 12 feet into the ground. Usually, a hole of 120 to 150mm diameter and 3 mtr depth is needed for driving the ground rod into the soil. This can vary depending on the dimension of the ground rod.

Superior Performance in Harsh Soil Conditions

Designed for aggressive soils, our chemical earthing systems utilize a special carbon-based backfill compound that retains moisture and resists corrosion remarkably well. This ensures high conductivity and low resistance grounding, critical for safeguarding electrical installations and enhancing overall system safety.

Compliance with International Standards

We strictly adhere to IS 3043, IEEE 80, and IEC 62561-2 standards, ensuring every installation meets rigorous quality and safety requirements. Our precision-engineered rods and compounds guarantee consistent performance and reliability, backed by comprehensive testing during installation.

FAQs of chemical earthing installation services:

Q: How is chemical earthing installed at my site?

A: Chemical earthing is installed either by directly driving the rod into the ground or by augering a hole and inserting the rod, which is then surrounded by a carbon-based conductive backfill compound. This process enhances moisture retention and ensures low resistance even in challenging soil types.Q: What types of materials are used in chemical earthing rods?

A: Our earthing rods are made from copper bonded steel or galvanized iron (GI), featuring a high-purity copper layer ranging from 100 to 250 microns. The rods have high mechanical strength and are paired with a specially formulated carbon-based backfill compound for optimal electrical conductivity.Q: Where are these chemical earthing solutions applicable?

A: Chemical earthing is suitable for electrical installations requiring reliable protection for equipment and personnel, especially in industrial, commercial, and residential environments with aggressive or high-resistivity soils across India.Q: What benefits does chemical earthing offer over conventional methods?

A: Chemical earthing achieves lower resistivity (less than 1 Ohm), superior moisture retention, and high corrosion resistance, resulting in enhanced safety, longer lifespan (over 25 years), and reduced maintenance compared to traditional earthing systems.Q: When should I test the chemical earthing installation?

A: Testing is performed on-site immediately after installation to confirm proper operation and adherence to standards. Periodic testing is recommended during the life span of the earthing system to ensure continued effectiveness.Q: What is the process for ordering chemical earthing installation services?

A: You can order a chemical earthing installation according to your requirements, with a minimum quantity of one set or more. We offer customized dimensions and configurations, delivered with standard carton/bag packing and comprehensive onsite service.Q: How does the backfill compound improve the earthing systems performance?

A: The carbon-based backfill compound retains moisture and maintains conductivity around the electrode, even in dry or aggressive soil, ensuring stable resistance levels and long-term electrical safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earthing Electrode Category

Industrial GI Earthing Electrode

Price 600.00 INR / Piece

Minimum Order Quantity : 50

Purity : 99%

Copper Thickness : 1.6mm Millimeter (mm)

Diameter : 80mm Millimeter (mm)

Color : Silver

copper bonded earth rod

Price 750.00 INR / Piece

Minimum Order Quantity : 50

Purity : 99%

Copper Thickness : 17.2 Millimeter (mm)

Diameter : 17.2mm

Color : Copper

Copper Earthing Bonded Rod

Price 1800 INR / Piece

Minimum Order Quantity : 1 Thousand

Purity : 99%

Copper Thickness : 1.6 Millimeter (mm)

Diameter : 76mm Millimeter (mm)

Color : Silver

earthing rod

Price 1800 INR / Thousand

Minimum Order Quantity : 100 Units

Purity : 99%

Copper Thickness : 1.6mm Meter

Diameter : 76mm Meter (m)

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS